Beauty and the Packaging Beast: Plastic in the Beauty Industry

By Cassandra Sisto, Shelley Haines, and Daniel Foucher

DOI: 10.38055/FS050110

MLA: Haines, Shelley, et al. “Beauty and the Packaging Beast: Plastic in the Beauty Industry.” Fashion Studies, vol. 5, no. 1, 2024, pp. 1-24, https://www.fashionstudies.ca/beauty-and-the-packaging-beast/, https://doi.org/10.38055/FS050110.

APA: Haines, Shelley, et al (2024). Beauty and the Packaging Beast: Plastic in the Beauty Industry. Fashion Studies 5(1). https://doi.org/10.38055/FS050110.

Chicago: Haines, Shelley, et al. “Beauty and the Packaging Beast: Plastic in the Beauty Industry.” Fashion Studies 5, no. 1 (2024). https://doi.org/10.38055/FS050110.

Volume 5, Issue 1, Article 10

Keywords

Plastic packaging

Cosmetic companies

Beauty industry

Microplastics

Bioplastics

abstract

The beauty industry’s reliance on plastic packaging has negatively impacted the environment and human health. Although plastic packaging is convenient and cost-effective for cosmetic companies, it creates significant waste that tends to be overlooked. In this paper, we review the most common plastics used in the beauty industry by looking at their environmental and health implications, as well as alternative bioplastics. Our review begins with an overview of acrylonitrile butadiene styrene (ABS) and styrene-acrylonitrile (SAN), two commonly used thermoplastics for cosmetic packaging. However, both ABS and SAN are challenging to recycle and often end up in landfills. Polyethylene terephthalate (PET) and polypropylene (PP) are versatile plastics with good pliability but are challenging to recycle. High-density polyethylene (HDPE) and low-density polyethylene (LDPE) are commonly used for their flexibility and durability, with HDPE being easier to recycle than LDPE. Polyvinyl chloride (PVC) is flexible, durable, and compatible with a variety of chemicals; however, it poses environmental risks due to its high chlorine content. Some cosmetic companies are turning to biopolymers and bioplastics to counter some of the adverse effects of traditional plastics. These materials can be made from by-products of other industries, often require less energy to produce, and have fewer adverse environmental and health impacts. These alternative materials are necessary to create a more sustainable beauty industry.

Introduction

In recent years, the beauty industry has thrived, propelled by the exponential growth of cosmetic companies, with many garnering widespread attention and achieving viral status across various social media platforms (Almeida, 2019; Vrontis et al., 2021). This surge, catalyzed by platforms like Instagram and YouTube, saw brands achieve viral status thanks to makeup tutorials, reviews, and endorsements from influential figures, fostering immense consumer engagement and reshaping beauty ideals (Kaur and Kumar, 2022).

Chemical ingredients in cosmetics have raised concerns about hormone disruption (Bilal et al., 2020; Nicolopoulou-Stamati et al., 2015). Moreover, the Food and Drug Administration (FDA; 2022) acknowledges the potential for skin irritation and allergic reactions linked to certain substances in beauty products, affecting consumers’ well-being. Microplastics, with nanoparticles found in some cosmetics, pose potential toxicity risks. These nanoparticles raise worries due to their skin penetration abilities and possible adverse effects (Bathi et al., 2022). Finally, the beauty industry’s prolific use of excessive packaging contributes significantly to environmental degradation and pollution, indirectly affecting human health by exacerbating environmental issues (Chen et al., 2021; Rajkumar, 2015). The relentless production and subsequent disposal of beauty products have led to releasing detrimental chemicals, such as parabens, phthalates, and formaldehyde, into ecosystems, posing severe ecological and health threats (Bilal, 2020). Further, the prevalent use of single-use plastic packaging by cosmetic companies, while pragmatic and cost-efficient, has resulted in a substantial accumulation of waste, often culminating in overflowing landfills and environmental degradation. This has resulted in several adverse effects, including landfill accumulation, microplastic pollution, resource depletion, and toxic chemical leaching (Evans et al., 2020).

A focus on aesthetics in the beauty industry, such as the appearance of product packaging, often overshadows environmental and health concerns (Vilutiene and Ignatavičius, 2018). Yet, when disposed of in landfills, cosmetic packaging can take hundreds of years to decompose, releasing harmful chemicals into the environment during this time. These chemicals include plasticizers and microplastics, which can seep into the soil and nearby water supplies. As well, due to their small size, microplastics have the potential to contaminate soil, water, and eventually food sources (Guerranti et al., 2019; Leslie, 2014).

In today’s beauty industry, most cosmetics use plastic packaging, primarily sourced from new, virgin plastics, rather than post-consumer recycled materials, such as recycled PET from water bottles (Geyer and Jambeck, 2017). Recycled plastic is advantageous in reducing waste by repurposing existing materials; however, its energy-saving potential and composting options are limited due to the degradation through the recycling process (Hopewell et al., 2009). While some companies have begun exploring alternative materials such as glass, metal, or bioplastics, most still heavily rely on virgin plastics due to their practicality and cost-effectiveness (Mohammed et al., 2018).

Some cosmetic companies, such as MOB Beauty and Glow Recipe, have introduced refillable product lines to counteract excessive packaging. Customers purchase a durable component (e.g., compact, jar, or bottle) along with refills. These refillable components, typically made of recycled PET and PP plastics, promote durability, decreasing the necessity for virgin plastics and unnecessary packaging (Gatt and Refalo, 2022). Recycling and reuse offer potential pathways for mitigating the environmental impact of plastic packaging. If used in production, recycled plastics can significantly reduce the need for virgin plastics, diminishing resource consumption and waste. Furthermore, the concept of refilling allows the packaging to be reused. Instead of discarding the entire packaging after using the product, consumers can refill the same container with a new batch or refill the same cosmetic product. This approach effectively extends the life of the packaging, significantly reducing the demand for new packaging and minimizing waste (Mrowiec, 2018). Yet, the cosmetic industry’s preference for plastic persists due to its practicality, cost-efficiency, and widespread availability, perpetuating the environmental concerns associated with excessive plastic use.

In this paper, we provide an overview of plastics specifically employed in cosmetic packaging within the beauty industry. By identifying and analyzing seven distinct plastic varieties commonly utilized for cosmetics packaging, we provide an overview of their individual attributes, strengths, limitations, and the consequential health and environmental impacts they pose. Despite their integral role in daily life, plastics pose a significant environmental threat due to their slow degradation and adverse impact on ecosystems and human health. Consequently, our discussion delves into alternative materials for beauty packaging, specifically biopolymers and bioplastics sourced from renewable resources. Overall, we aim to analyze and synthesize existing research concerning both traditional and alternative plastics, and present them in a comprehensive overview. Thus, we aim to offer a holistic understanding of the challenges and opportunities in cosmetic packaging. Finally, we highlight the practical implications and next steps for addressing the issue of plastic waste.

Traditional Plastics

Acrylonitrile Butadiene Styrene (ABS)

Acrylonitrile butadiene styrene (ABS), a thermoplastic polymer, is one of the leading choices for cosmetic packaging in the beauty industry. This type of plastic is known for its durability and glass-like appearance, due to its clarity and shine (see Figure 1 for the structure of ABS; Moore, 1973). It is used for various purposes, including children’s toys and 3D printing. ABS is ideal for cosmetics packaging because it is a durable material that can withstand transportation and handling. Moreover, the durability of ABS makes it suitable for use in both professional makeup kits and the makeup bags of everyday consumers, where cosmetics are frequently handled. Packaging made from ABS plastic can withstand the demands of travel and repeated use, which helps to ensure that the cosmetic contents remain protected. As well as being durable, the clarity of ABS allows the actual colour of a cosmetics product to be visible. This is especially important for products sold in clear packaging, such as lip balms, or when a product’s colour is a crucial selling point, like nail polishes. At the molecular level, ABS is an amorphous thermoplastic polymer, meaning that it is non-crystalline with a high shine, either produced in a colour, such as black, or completely colourless and transparent. This plastic has no precise melting point, rendering it largely resistant to thermal expansion and contraction, making it ideal for manufacturing. In terms of its chemical composition, this polymer is resistant to many types of mineral oils, commonly used in cosmetics, making it suitable for housing most types of cosmetics products and formulas, such as creams, powders, and liquids (Singh et al., 2022). Companies frequently use ABS to house loose or pressed powders and other delicate products that need extra protection, such as liquid products like foundation and lip gloss. In addition to the above advantages, ABS is considered a cost-effective polymer. On average, ABS costs less than two dollars per kilogram when sourced from manufacturers in China and other Asian countries.

Figure 1

Structures of Acrylonitrile butadiene styrene (ABS, Left) and Styrene-acrylonitrile (SAN, right).

Moreover, even when purchasing fully assembled components from a packaging plant, the costs of these packaging elements remain low, particularly when purchased in bulk. Thus, ABS appeals to many companies in the beauty industry, ranging from drugstores to high-end luxury brands, seeking to maximize their revenue and produce high volumes of cosmetic products (Khanna, 2022). ABS is a popular choice for packaging cosmetics due to its resilience during transportation and everyday use. Its strength protects the cosmetics inside, and its see-through quality is preferred for products where colour visibility is important. ABS is resistant to many chemicals. Finally, it is an affordable plastic, making it attractive to companies.

Styrene-Acrylonitrile (SAN)

Styrene-acrylonitrile (SAN) is another type of acrylic plastic resin commonly used for packaging in the beauty industry, along with other purposes such as kitchenware and computer products. Classified as a copolymer plastic, SAN is regarded as a good choice for cosmetic packaging because of its strength, second only to ABS (see Figure 1 for the structure of ABS; Maidin and Muhammad, 2023). SAN plastics are mainly used as materials for lids of cosmetic components, particularly when a clear plastic lid is required. Furthermore, SAN is frequently used to house solid and gel-based cosmetics, including eyebrow gel and pomade, as these products require less durable packaging (McKeen, 2012). Overall, SAN is well-suited for packaging a wide range of cosmetic products due to its clarity, durability, and resistance to a range of chemicals. Overall, its durability, clear appearance, and resistance to various chemicals make SAN a good fit for packaging many cosmetics.

Challenges in Recycling ABS and SAN and the Complexity of Cosmetic Packaging

While both ABS and SAN share many of the same advantages, as they are both relatively durable and inexpensive to produce, they pose various health risks throughout their lifecycle. During production, these plastics may emit harmful chemicals or fumes, impacting the health of workers involved. Concerns also arise regarding the potential leaching of certain chemicals from these plastics when used in products that come into contact with the skin or are ingested. (Azoulay et al., 2019). Both ABS and SAN fall under the category of “Plastic #7” within the plastic recycling code system (American Chemistry Council). This category is used for plastics that do not fit into any of the other established categories and are generally challenging to recycle, as many recycling facilities are not equipped to handle them. Thus, Plastic #7 plastics are one of the least recycled categories of plastic, and they often end up in landfills, where they can take hundreds of years to decompose. For instance, ABS, often used in black cosmetic packaging, is difficult to recycle because its dark colour cannot be detected by most infrared optical sorting systems in recycling plants. As a result, the plastic cannot be recycled and is instead sent to a landfill. As for SAN, despite usually being colourless and easily detectable during sorting, it is also challenging to process. While SAN plastic is well-suited for recycling due to its optical properties, it is rare to find cosmetic packages made solely of SAN plastic (García et al., 2016).

Cosmetic packages are usually made of different materials stuck together with glue, making it challenging to separate them. This mix of materials often means the package cannot be reused or recycled, ending its usefulness sooner. Ultimately, separating the metal pan from an ABS plastic compact and thoroughly cleaning out any residual product can greatly increase the recyclability of the plastic component. This is particularly important for plastics that fall under the “Plastic #7” category, which includes a variety of plastics that can be difficult to recycle and may contain harmful additives.

Health Risks and Environmental Impact of ABS and SAN Plastics

Both ABS and SAN release harmful chemicals. Exposure to the chemicals present in these plastics, both during their production and breakdown, has been associated with respiratory problems, endocrine disruption, and even cancer (Giulivo et al., 2016; Godswill and Godspel, 2019). Moreover, their non-biodegradable nature contributes to long-term pollution, persisting in the environment and potentially affecting ecosystems and wildlife. The breakdown of ABS and SAN plastics into microplastics further exacerbates these concerns, as these particles can infiltrate soil, waterways, and the food chain, posing risks to both wildlife and human health (Azoulay et al., 2019). Microplastics, small plastic particles from the breakdown of larger plastic items, are a growing concern as they can easily enter the soil, waterways, and food chains, endangering both wildlife and humans (Gatt and Refalo, 2022). Overall, the health hazards and environmental repercussions stemming from ABS and SAN plastics, two of the most commonly used plastics, underscore the urgent need for conscientious alternatives and a comprehensive re-evaluation of cosmetic packaging materials within the beauty industry.

Polyethylene Terephthalate (PET) and Polypropylene (PP)

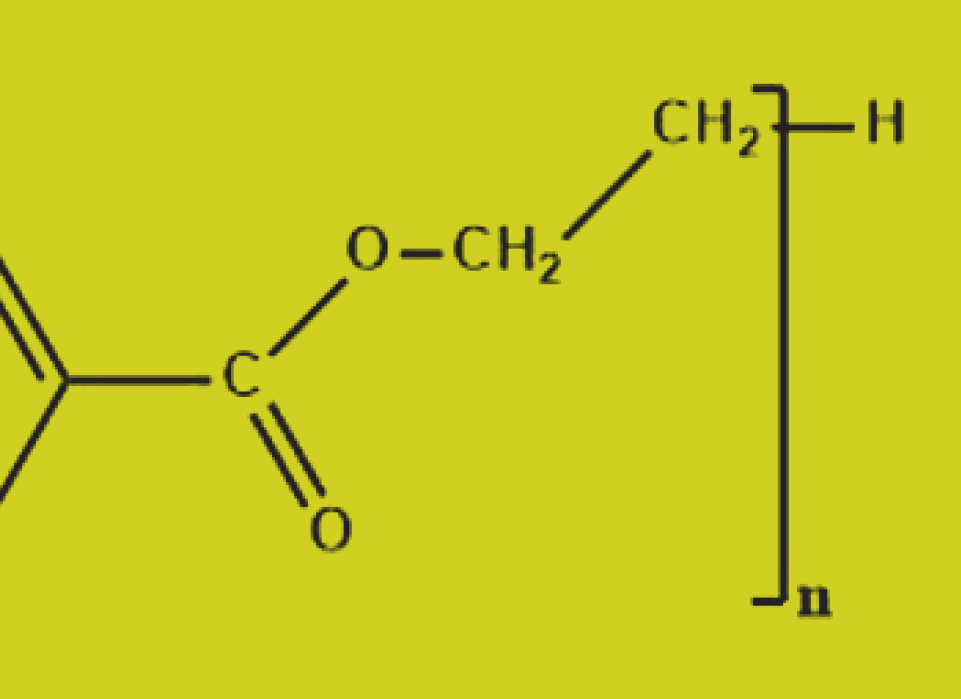

Beyond ABS and SAN plastics, there are a variety of options available for companies in the beauty industry to choose from, including nearly all six of the remaining numbered plastic categories, each tailored to a unique packaging function. Polyethylene terephthalate (PET) and polypropylene (PP), categorized as “Plastic #1” and “Plastic #5,” respectively, are also commonly used plastics in the packaging of cosmetic products. While these plastics are used for different purposes, they share one common trait: exceptional pliability. These lightweight thermoplastic polymers are often used to design unique shapes for packaging, rendering them suitable for creating custom compacts, palettes, bottles, and unique-sized pumps and tubes, making these two types of plastics versatile for the cosmetic industry (see Figure 2 for the structures of PET and PP). Moreover, PET and PP are two of the most recyclable of all the seven recycling categories of plastics (Chu et al., 2023). Thus, many cosmetic companies with sustainable values often rely on PET and PP plastics for their packaging, often supplemented by the utilization of post-consumer recycled (PCR) plastics from sources like water bottles to reduce reliance on new, virgin materials. However, amidst these efforts, vigilance against greenwashing practices remains crucial to ensure genuine environmental commitments, considering that recycled plastics may release microplastics and contain antimony, a carcinogenic compound, posing pollution concerns despite their reduced energy use (Dupont et al., 2016).

Figure 2

Structures of Polyethylene terephthlate (PET, Left) and Polypropylene (PP, Right).

Health and Environmental Considerations of PET and PP in Cosmetic Packaging

Despite the integration of PCR plastics, a persisting challenge arises from the complexity of cosmetic packaging, mirroring the issue faced with SAN and ABS plastics. That is, cosmetic packaging is often made of several different materials. This presents an issue concerning the recycling process of these materials. For example, a pressed powder foundation compact can have up to six different material components, including plastics for the compact itself, glass for the mirror, and metal for the pan that holds the product. Separating these pieces during recycling is difficult, as different materials require different recycling processes. Consequently, when different materials are mixed it can be challenging to separate them and recycle each component effectively. Thus, these products are often discarded in landfills rather than recycled (Khanna, 2022). Despite the potential for recyclability, drawbacks such as the rejection of microplastics and the presence of carcinogenic compounds like antimony in recycled plastics, along with complexities in recycling practices leading to pollution, persist as significant challenges with PET and PP. Thus, it is necessary to address these limitations to mitigate environmental and health impacts and promote more effective recycling solutions in the cosmetic packaging industry.

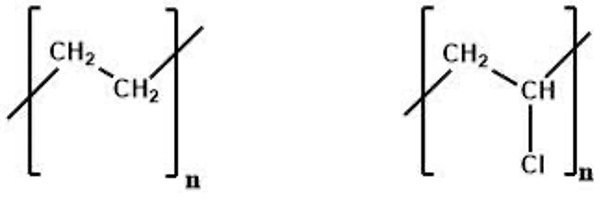

High- and Low-Density Polyethylene (HDPE and LDPE)

Along with PET, two other forms of polyethylene in the numbered plastic categorization are often used in the beauty industry, including high- and low-density polyethylene (HDPE and LDPE; see Figure 3 for the structure of these plastics). HDPE is categorized as “Plastic #2”, while LDPE is classified as “Plastic #4”. These variations share an ethylene-based structure but vary in the degree of branching along their polymer chains, distinguishing them by their relative densities. Each of these polymers exhibit different traits and capabilities, where low-density PE polymers are associated with being highly flexible and squeezable, while high-density PE polymers are characterized by their strength and sturdiness while maintaining a slightly lower degree of flexibility. These plastics are desirable for highly sensitive products that require protection from light, for example, as this plastic can be manufactured to be opaque in appearance (Achilias et al., 2007). These two plastics are most often used for hair care products, such as shampoo and conditioner bottles, and skincare products, such as face cleanser bottles and moisturizer squeeze tubes. They are known for their flexibility, versatility, and durability. While they are mainly produced and sold in white containers with labels added, they are sometimes produced in a variety of colours. Their main difference, as noted in their names, is their density, where one is high, and one is low. This difference is most evident in their respective flexibilities, as the density is proportional to the flexibility of the plastic.

HDPE is generally easier to recycle than LDPE. Since LDPE is softer and more flexible, it can be more difficult to process in recycling facilities because it can get caught in sorting and processing machines. Conversely, HDPE is more rigid and, therefore easier to recycle because it can be more easily separated from other materials and processed. A solution for some difficult-to-recycle plastics, such as low-density polyethylene (LDPE), is chemical recycling. Chemical recycling is the process of using chemicals of high concentration to dissolve plastics into their constituent polymers (Santagata et al., 2020). However, this practice is potentially dangerous to the environment, as the chemicals can infiltrate water supplies and surrounding soil, which may jeopardize the lives of human health and marine animals (Achilias et al., 2015).

Figure 3

Structures of Polyethylene (HDPE and LDPE, Left) and Polyvinylchloride (PVC, right).

Polyvinyl Chloride (PVC)

The final type of plastic commonly seen in the beauty industry is polyvinyl chloride (PVC), which is categorized as “Plastic #3”. Plastic #3 materials are used in many fields besides the beauty industry, and two forms of this plastic exist for a wide range of applications: rigid and flexible. The former is applied when durability and strength are required, like for pipes used in construction. Conversely, the latter is much flimsier and thinner but still durable for the protection of cosmetic products. Plasticizers are added to this flexible polymer so that the plastic can stretch out to fully encase cosmetic packages to protect from any contaminants, scuffs, scratches, and other external factors that would interfere with the product and its appearance (Fischer et al., 2014; McKeen, 2014). PVC is known for its incredible tensile strength and flexibility when plasticizers are added (see Figure 3 for the structure of PVC). While typically used in the production of windows and doors, PVC finds application in the outer packaging and labelling of cosmetic products.

This type of packaging is widely seen and used by lower-end cosmetic companies as their main external packaging.

PVC prompts interesting considerations due to its high chlorine content and the presence of plasticizers, which can be toxic. Mechanical recycling is often preferred for PVC because, similarly to ABS, the plastic components can be ground into smaller pieces, which can then be melted down and used to create new products. This method is particularly useful for PVC because it does not involve the potential synthesis of any possibly dangerous or toxic by-products, such as in hydrogen chloride gas, other plasticizer chemicals, or solvents. This material could have a much higher global impact due to its potential toxicity, but it seems to carry low overall risk since it is not the main choice for cosmetic packaging despite being used excessively in other industries and fields (Lewandowski and Skórczewska, 2022). Lower-end cosmetic companies, mainly sold in drug stores and other low-end retailers, appear to contribute the most to pollution by utilizing PVC for outer packaging. In contrast, higher-end cosmetic companies use cardboard and/or paper derivatives for their outermost packaging, as they can afford to include additional packaging in the final price of their products. For low-end cosmetic products, using PVC substitutes the need for an outer package, where this plastic shrink-wrap serves as the protective outer layer. As these products are accessible to individuals at any income level, they are purchased more widely and contribute to higher pollution levels via PVC (Mangaraj et al., 2009). Figure 4 provides an overview of the plastic components discussed per cosmetic packaging component.

Figure 4

Example of Plastic Use per Cosmetic Packaging Component.

Bioplastics and Biopolymers

As far as materials go, traditional plastics are designed to be strong and durable. This is often achieved by adding compounds that increase the monomers’ and bonds’ strength and durability. For example, plasticizers can be added to make plastic more flexible, while stabilizers can help prevent degradation from exposure to light, heat, and chemicals. However, the addition of these compounds also makes traditional plastics more difficult to recycle or biodegrade, which can contribute to negative health effects and environmental pollution. Strategically, some companies in the cosmetics industry have elected to find new ways to reduce their use of plastic. In fact, in the last few years, many upscale and luxury cosmetic companies have adopted biopolymers and other types of sustainable packaging to reduce their environmental impact. For cosmetic companies, their packaging must be durable, easy to keep clean and protect the product without leaking, spilling, or breaking the internal contents. Thus, when replacing traditional plastic cosmetic packaging, the alternative materials must perform comparably to plastic for all the previously mentioned criteria (Wróbel-Kwiatkowska et al., 2009).

Biopolymers and bioplastics offer a possible alternative to traditional plastics for cosmetic packaging. Biopolymers are polymers derived from natural sources, such as proteins, DNA, and cellulose, and bioplastics are made from renewable biomass sources, such as plant materials. While some biopolymers and bioplastics are even biodegradable, meaning natural processes can break them down into harmless compounds, others are not. The adoption of biopolymers and bioplastics in the cosmetic industry, given their biodegradability, could substantially reduce the annual production of harmful plastics, potentially minimizing the reliance on traditional recycling methods, particularly chemical processes (Baranwal et al., 2022). Primarily in the North American cosmetic market, biopolymers have been implemented in the packaging of smaller items, such as single compacts and lipstick tubes, rather than larger cosmetic items, such as eyeshadow and face palettes, that require more supportive packaging to avoid damage.

Another benefit of using biopolymers and bioplastics in the beauty industry is that many of the materials used to manufacture them are often by-products from other industries, such as the agriculture industry. For instance, some biopolymers are made from plant materials, which can be obtained from the waste generated by the food industry. For example, flax shive has been used to make bioplastics in the beauty industry (Sain and Fortier, 2002). Flax shive is left over after flax harvesting and is considered a by-product because it is unsuitable for human consumption. Thus, using flax shive to make bioplastics is a sustainable, circular production process because it uses materials that would otherwise be discarded. Moreover, compared to traditional plastics, bioplastics made from flax require less energy and produce fewer greenhouse gases (Kulma et al., 2015). In addition to being more sustainable during production, bioplastics made from flax are biodegradable. Comprising solely of flax shive and other organic modifiers, they do not damage the surrounding soil and water supplies, as many other plastics do.

Bioplastics and biopolymers can also replicate the appearance of many different types of traditional plastics. Their properties can be manipulated to be ‘bendy’ and pliable, like LDPE, or structurally strong, like PET. Furthermore, different materials can be added to adjust the strength and other properties, akin to the transformation from SAN to ABS, but with no harm done to the environment. In addition, cellulose has recently been investigated for its properties and potential to replace plastics in cosmetic packaging, where it can be added to existing biopolymers as a modifier. It has the potential to provide the foundation for other new cellulose-based biopolymers and bioplastics (Wróbel-Kwiatkowska et al., 2009). Further, bioplastics are deemed safer as they emit fewer greenhouse gases during production and can break down naturally, presenting a greener alternative to traditional plastics (Auras, Harte, and Selke, 2004). While it is still too early to be certain that these polymers will be suitable for cosmetics or even suitable for specific formulas, research and development teams around the world are seeking suitable alternatives for plastic in the beauty industry to maximize its sustainability (Amara et al., 2021). Table 1 summarizes the advantages and disadvantages of the plastics discussed in this paper.

ABS and SAN are known to be some of the most problematic plastics, contributing to pollution both during production and at the end of their life cycle. Though many cosmetic companies understand the harmful health and environmental effects of their current packaging practices, few have adopted sustainable packaging alternatives. While some companies have started using sustainable packaging materials, there is still a long way to go to create a more sustainable industry.

Introducing sustainable packaging solutions into the beauty industry confronts multifaceted challenges that intertwine traditional practices with the integration of newer, environmentally friendly alternatives. The market’s entrenched reliance on well-established plastics like ABS, SAN, PET, PP, HDPE, and LDPE poses a substantial hurdle, primarily due to their durability, cost-effectiveness, and established infrastructure for production and recycling. Overcoming this inertia demands a delicate balance between addressing the shortcomings of these conventional plastics, such as potential health risks, environmental concerns, and complexities in recycling, while fostering awareness and adoption of emerging sustainable materials like bioplastics and biopolymers. However, this shift necessitates a comprehensive overhaul of manufacturing processes, supply chains, and consumer perceptions. Moreover, challenges arise in reconciling the practicalities of implementing sustainable solutions within an industry that often relies on complex, multi-material packaging designs, where recycling complexities and inadequate infrastructure hinder the effective recovery and reuse of materials. Therefore, a crucial aspect of introducing sustainable packaging solutions lies in navigating the transition away from traditional plastics, managing the complexities of mixed-material packaging, and fostering a paradigm shift towards embracing innovative, eco-friendly alternatives while addressing practical industry constraints.

Cosmetic companies can significantly advance sustainability by shifting away from traditional plastics and embracing eco-friendly alternatives. This entails adopting sustainable packaging materials like bioplastics and biopolymers and reducing the amount of packaging used in their products, more generally. Cosmetic companies must also work to educate consumers about the importance of sustainability and encourage them to make more conscious choices. Companies can leverage their social media presence and documented success (e.g., Almeida, 2019; Vrontis, 2021) to educate consumers while simultaneously promoting their own sustainable initiatives. Yet, consumers themselves play a critical role in supporting cosmetic companies that prioritize sustainable materials and practices. By choosing these companies, consumers can communicate to the beauty industry that they value and support sustainability.

Additionally, by educating themselves about the impacts of different materials and practices, consumers can make choices that align with their values. In turn, this will drive demand for sustainable products and influence cosmetic companies to adopt more sustainable practices. While consumer demand for sustainable options can help drive change, it remains the responsibility of cosmetic companies to take action to reduce their negative impacts on the environment and human health. If companies do not consider the full lifecycle of their products, from design and product to end-of-life disposal, their use of unsustainable plastics will continue to have negative impacts. Cosmetic companies must prioritize sustainable solutions, such as biodegradable packaging, recycled materials, refillable or reusable packaging, carbon-neutral initiatives, life cycle analysis, education, and transparency to minimize waste and contribute to a more responsible beauty industry. Finally, in conjunction, governments and policymakers must play a role in promoting the use of sustainable materials and incentivizing cosmetic companies to adopt more sustainable practices. Implementing regulations and standards that advocate for adopting alternative materials, such as bioplastics and biopolymers, while discouraging the continued use of traditional plastics stands as an active and strategic approach. Bioplastics, derived from sources like corn starch, sugarcane, or vegetable fats, exemplify a shift away from dependency on finite fossil fuel resources, thereby reducing the environmental burden associated with extracting these non-renewable sources. For instance, studies like Auras et al. (2004) highlight the potential of polylactides derived from bioplastics as effective packaging materials, showcasing their renewable and eco-friendly attributes. Some bioplastics also exhibit biodegradability, offering a significant advantage in reducing environmental impact, while emitting fewer greenhouse gases during production, thus resulting in lower overall carbon footprints compared to traditional plastics. These attributes signify a substantial step towards a more sustainable and environmentally conscious beauty industry.

Corporate sustainable innovation, fundamentally rooted in institutional, stands as a cornerstone for driving progress. Studies, such as Delmas and Pekovic's (2018) comprehensive into the impact of eco-labelling, government incentives, and tax breaks on companies’ environmental performance, shed light on the potential implications for the beauty industry (Delmas and Pekovic, 2018). Additionally, understanding the efficacy of educational campaigns is equally vital. Kjaer’s empirical research in 2020 highlights the impact of these campaigns on consumer behaviour and awareness, offering valuable insights (Kjaer, 2020). This multifaceted approach, integrating diverse strategies and backed by empirical evidence, stands poised to significantly contribute to a more sustainable future for the cosmetics sector. For example, Scholtz et al. (2016) found a positive impact of social media-based environmental campaigns in enhancing environmental awareness.

Similarly, Lee et al. (2012) highlight the positive influence of fashion retailers’ green retailing efforts, particularly the perception of green private brands and campaigns, on consumers’ green behaviour and consciousness. Further, governments and policymakers should educate consumers on the importance of sustainable practices and encourage them to support cosmetic companies that prioritize sustainability. Certifications, such as B-Corp, bolster brand credibility and consumer trust. By validating a brand’s dedication to sustainability, ethics, and responsible practices, these certifications set stringent standards across environmental performance, social impact, and governance (Paelman et al., 2021; Villea et al., 2021). They assure consumers of a brand’s adherence to rigorous sustainability benchmarks, offering transparency and confidence in their ethical commitments. Moreover, these certifications often include ongoing assessments, reinforcing a brand’s continuous dedication to sustainable practices, fostering consumer loyalty, and giving them a competitive edge in an eco-conscious market (Paelman et al., 2021; Villea et al., 2021).

Table 1

Summary of the Advantages and Disadvantages of Plastics by Group and Type

Note: The data in the “Major Suppliers” column is sourced from Statista’s report on the distribution of global plastic materials production in 2021 by region (Statista Research Department, 2023).

Screen-readable version in PDF version of article.

References

Achilias, D. S., Roupakias, C., Megalokonomos, P., Lappas, A. A., and Antonakou, E. V. (2007). Chemical recycling of plastic wastes made from polyethylene (LDPE and HDPE) and polypropylene (PP). Journal of Hazardous Materials, 149(3), 536-542.

Almeida, M. N. D. (2019). Influencer marketing on Instagram: how influencer type and perceived risk impact choices in the beauty industry (Doctoral dissertation).

Amara, C., El Mahdi, A., Medimagh, R., and Khwaldia, K. (2021). Nanocellulose-based composites for packaging applications. Current Opinion in Green and Sustainable Chemistry, 31, 100512.

American Chemistry Council. (n.d.). Plastics. Retrieved March 6, 2023, from https://www.americanchemistry.com/chemistry-in-america/chemistry-in-everyday-products/plastics

Auras, R., Harte, B., and Selke, S. (2004). An overview of polylactides as packaging materials. Macromolecular Bioscience, 4(9), 835-864.

Azoulay, D., Villa, P., Arellano, Y., Gordon, M. F., Moon, D., Miller, K. A., and Kistler, A. (2019). Plastic andril health: The hidden costs of a plastic planet. Geneva: CIEL.

Baranwal, J., Barse, B., Fais, A., Delogu, G. L., and Kumar, A. (2022). Biopolymer: A sustainable material for food and medical applications. Polymers, 14(5), 983.

Bathi, J. R., Wright, L., and Khan, E. (2022). Critical review of engineered nanoparticles: environmental concentrations and toxicity. Current Pollution Reports, 8(4), 498-518.

Bilal, M., Mehmood, S., and Iqbal, H. M. (2020). The beast of beauty: environmental and health concerns of toxic components in cosmetics. Cosmetics, 7(1), 13.

Chu, J., Zhou, Y., Cai, Y., Wang, X., Li, C., and Liu, Q. (2023). Flows and waste reduction strategies of PE, PP, and PET plastics under plastic limit order in China. Resources, Conservation and Recycling, 188, 106668.

Chen, Y., Awasthi, A. K., Wei, F., Tan, Q., and Li, J. (2021). Single-use plastics: Production, usage, disposal, and adverse impacts. Science of the Total Environment, 752, 141772.

Delmas, M. A., and Pekovic, S. (2018). Corporate sustainable innovation and employee behavior. Journal of Business Ethics, 150, 1071-1088.

Dupont, D., Arnout, S., Jones, P. T., and Binnemans, K. (2016). Antimony recovery from end-of-life products and industrial process residues: a critical review. Journal of Sustainable Metallurgy, 2, 79-103.

Evans, D. M., Parsons, R., Jackson, P., Greenwood, S., and Ryan, A. (2020). Understanding plastic packaging: The co-evolution of materials and society. Global Environmental Change, 65, 102166.

Fischer, I., Schmitt, W. F., Porth, H. C., Allsopp, M. W., and Vianello, G. (2014). Poly (vinyl chloride). Ullmann’s Encyclopedia of Industrial Chemistry, 1-30.

Food and Drug Administration. (2022). Allergens in Cosmetics. Retrieved from https://www.fda.gov/cosmetics/cosmetic-ingredients/allergens-cosmetics

García, M. D. G. T., Schlatter, M., Cabrera, F. M., Manzanares, J. T., and Hanafi, I. (2016). Recycling of acrylonitrile–butadiene–styrene using injection moulding machine. Procedia Technology, 22, 399-406.

Gatt, I. J., and Refalo, P. (2022). Reusability and recyclability of plastic cosmetic packaging: A life cycle assessment. Resources, Conservation & Recycling Advances, 15, 200098.

Geyer, R., Jambeck, J. R., and Law, K. L. (2017). Production, use, and fate of all plastics ever made. Science Advances, 3(7), e1700782.

Giulivo, M., de Alda, M. L., Capri, E., and Barceló, D. (2016). Human exposure to endocrine disrupting compounds: Their role in reproductive systems, metabolic syndrome and breast cancer. A review. Environmental Research, 151, 251-264.

Godswill, A. C., and Godspel, A. C. (2019). Physiological effects of plastic wastes on the endocrine system (Bisphenol A, Phthalates, Bisphenol S, PBDEs, TBBPA). International Journal of Bioinformatics and Computational Biology, 4(2), 11-29.

Goodship, V. (2007). Plastic recycling. Science Progress, 90(4), 245-268.

Guerranti, C., Martellini, T., Perra, G., Scopetani, C., and Cincinelli, A. (2019). Microplastics in cosmetics: Environmental issues and needs for global bans. Environmental Toxicology and Pharmacology, 68, 75-79.

Hopewell, J., Dvorak, R., and Kosior, E. (2009). Plastics recycling: challenges and opportunities. Philosophical Transactions of the Royal Society B: Biological Sciences, 364(1526), 2115-2126.

Kaur, K., and Kumar, P. (2022). Social media: a blessing or a curse? Voice of owners in the beauty and wellness industry. The TQM Journal, 34(5), 1039-1056.

Khanna, A. S. Natural Degradation on Plastics and Corrosion of Plastics in Industrial Environment. Encyclopedia of Materials: Plastics and Polymers 2022, 956–986. https://doi.org/10.1016/b978-0-12-820352-1.00105-x.

Kulma, A., Skórkowska-Telichowska, K., Kostyn, K., Szatkowski, M., Skała, J., Drulis-

Kawa, Z., and Szopa, J. (2015). New flax producing bioplastic fibers for medical purposes. Industrial Crops and Products, 68, 80-89.

Lee, N., Choi, Y. J., Youn, C., and Lee, Y. (2012). Does green fashion retailing make consumers more eco-friendly? The influence of green fashion products and campaigns on green consciousness and behavior. Clothing and Textiles Research Journal, 30(1), 67-82.

Leslie, H. A. (2014). Review of microplastics in cosmetics. IVM Institute for Environmental Studies, 476, 1-33.

Lewandowski, K., amd Skórczewska, K. (2022). A Brief Review of Poly (Vinyl Chloride)(PVC) Recycling. Polymers, 14(15), 3035.

Maidin, S., and Muhammad, A. H. (2023). Comparative Analysis of Acrylonitrile Butadiene Styrene and Polylactic Acid Samples’ Mechanical Properties Printed in Vacuum. Additive Manufacturing.

Mangaraj, S., Goswami, T. K., and Mahajan, P. V. (2009). Applications of plastic films for modified atmosphere packaging of fruits and vegetables: a review. Food Engineering Reviews, 1, 133-158.

McKeen, L. W. (2014). Plastics used in medical devices. In Handbook of polymer applications in medicine and medical devices (pp. 21-53). William Andrew Publishing.

McKeen, L. Styrenic Plastics. The Effect of Sterilization on Plastics and Elastomers 2012, 85–132. https://doi.org/10.1016/b978-1-4557-2598-4.00004-6.

Mohammed, A. N. B., Medina, G. I., and Romo, G. Z. (2018). The effect of cosmetics packaging design on consumers’ purchase decisions. Indian Journal of Marketing, 48(12), 50-61. https://doi.org/10.17010/ijom/2018/v48/i12/139556

Moore, J. D. (1973). Acrylonitrile-butadiene-styrene (ABS)-a review. Composites, 4(3), 118-130.

Mrowiec, B. (2018). Plastics in the circular economy (CE). Environmental Protection and Natural Resources, 29(4), 16-19.

Nicolopoulou-Stamati, P., Hens, L., and Sasco, A. J. (2015). Cosmetics as endocrine disruptors: are they a health risk?. Reviews in Endocrine and Metabolic Disorders, 16, 373-383.

Paelman, V., Van Cauwenberge, P., and Vander Bauwhede, H. (2021). The impact of B corp certification on growth. Sustainability, 13(13), 7191.

Rajkumar, P. (2015). A study on the plastic waste and environmental degradation. ABC Journal of Advanced Research, 4(1), 9-16.

Sain, M., and Fortier, D. (2002). Flax shives refining, chemical modification and hydrophobisation for paper production. Industrial Crops and Products, 15(1), 1-13.

Santagata, C., Iaquaniello, G., Salladini, A., Agostini, E., Capocelli, M., and De Falco, M. (2020). Production of low-density polyethylene (LDPE) from chemical recycling of plastic waste: process analysis. Journal of Cleaner Production, 253, 119837.

Singh, J., Chawla, K., & Singh, R. (2022). Applications of thermoplastic polymers in 3D printing.

Scholtz, B., Burger, C., and Zita, M. (2016). A social media environmental awareness campaign to promote sustainable practices in educational environments. In Advances and New Trends in Environmental and Energy Informatics: Selected and Extended Contributions from the 28th International Conference on Informatics for Environmental Protection (pp. 355-369). Springer International Publishing.

Statista Research Department. (2023, September 18). Distribution of global plastic materials production in 2021, by region. Plastic Material Production Worldwide by Region 2021. Retrieved from https://www.statista.com/statistics/281126/global-plastics-production-share-of-various-countries-and-regions/

Villela, M., Bulgacov, S., and Morgan, G. (2021). B Corp certification and its impact on organizations over time. Journal of Business Ethics, 170, 343-357.

Vilutiene, T., and Ignatavičius, Č. (2018). Towards sustainable renovation: Key performance indicators for quality monitoring. Sustainability, 10(6), 1840.

Vrontis, D., Makrides, A., Christofi, M., and Thrassou, A. (2021). Social media influencer marketing: A systematic review, integrative framework and future research agenda. International Journal of Consumer Studies, 45(4), 617-644.

Wróbel-Kwiatkowska, M., Skórkowska-Telichowska, K., Dymińska, L., Mączka, M., Hanuza, J., and Szopa, J. (2009). Biochemical, mechanical, and spectroscopic analyses of genetically engineered flax fibers producing bioplastic (poly-ß-hydroxybutyrate). Biotechnology Progress, 25(5), 1489-1498.

Author Bios

Cassandra Sisto is a B.Sc. student in Chemistry at Toronto Metropolitan University. She is also a passionate junior chemist with a special interest in cosmetics. She believes in the power of taking a scientific approach to beauty, and her current research mainly focuses on the formulation and creation of clean and eco-friendly cosmetics. Outside of the lab, she is an advocate for stronger consumer protections in the cosmetic industry and strives to bring ethical and natural beauty products to the masses. She truly believes that “clean beauty” can have a positive impact on the world.

Shelley Haines is a sustainable fashion lecturer and researcher. Her scholarly commitment to understanding and promoting sustainability dates back a decade and, since 2016, she has taught a diverse set of courses on ethics and sustainability, product forecasting, marketing, social media promotion, computer-aided design, and research methods. In 2023, Shelley completed a PhD with a focus on sustainable fashion consumption behaviour.

Daniel Foucher is a Professor of Chemistry in the Department of Chemistry and Biology at Toronto Metropolitan University. He has extensive experience in both the industrial and academic research of polymers. His current focus lies on the preparation of sustainable polymers, conductive materials and antimicrobial coatings and polymers. He has been a professor of Chemistry at TMU since 2007.

Article Citation

Haines, Shelley, et al. “Beauty and the Packaging Beast: Plastic in the Beauty Industry.” Fashion Studies, vol. 5, no. 1, 2024, pp. 1-24, https://www.fashionstudies.ca/beauty-and-the-packaging-beast/, https://doi.org/10.38055/FS050110.

Copyright © 2024 Fashion Studies - All Rights Reserved

Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International (CC BY-NC-ND 4.0) license (see: https://creativecommons.org/licenses/by-nc-nd/4.0/)